Rotogravure Printing

Rotogravure printing is an intaglio printing technique used in the packaging industry. This method is preferred for achieving high quality and detailed prints and is particularly ideal for creating impressive graphics, images and text on packaging materials.

Rotogravure printing works through grooves on a cylinder. The grooves are used for storing and transferring ink. These cavities contain a combination of dots with different depths and widths. Depending on the design, the density and arrangement of these dots can vary. Deep dots store more ink, while shallow dots store less ink. Thus, different tones, shades and details can be created.

The rotogravure printing process consists of several stages:

Design Preparation: The first step is to prepare the design to be used in the print. A high-resolution image is usually created using digital design software. This design is made suitable for printing and color separations are made.

Cylinder Engraving: The design is transferred onto a copper coating on a printing cylinder using an engraving machine. Then, using methods such as acid or laser, gouges are created. The gouges contain a combination of dots with different depths and widths. Deeper dots store more ink and create darker tones, while shallower dots store less ink and create lighter tones.

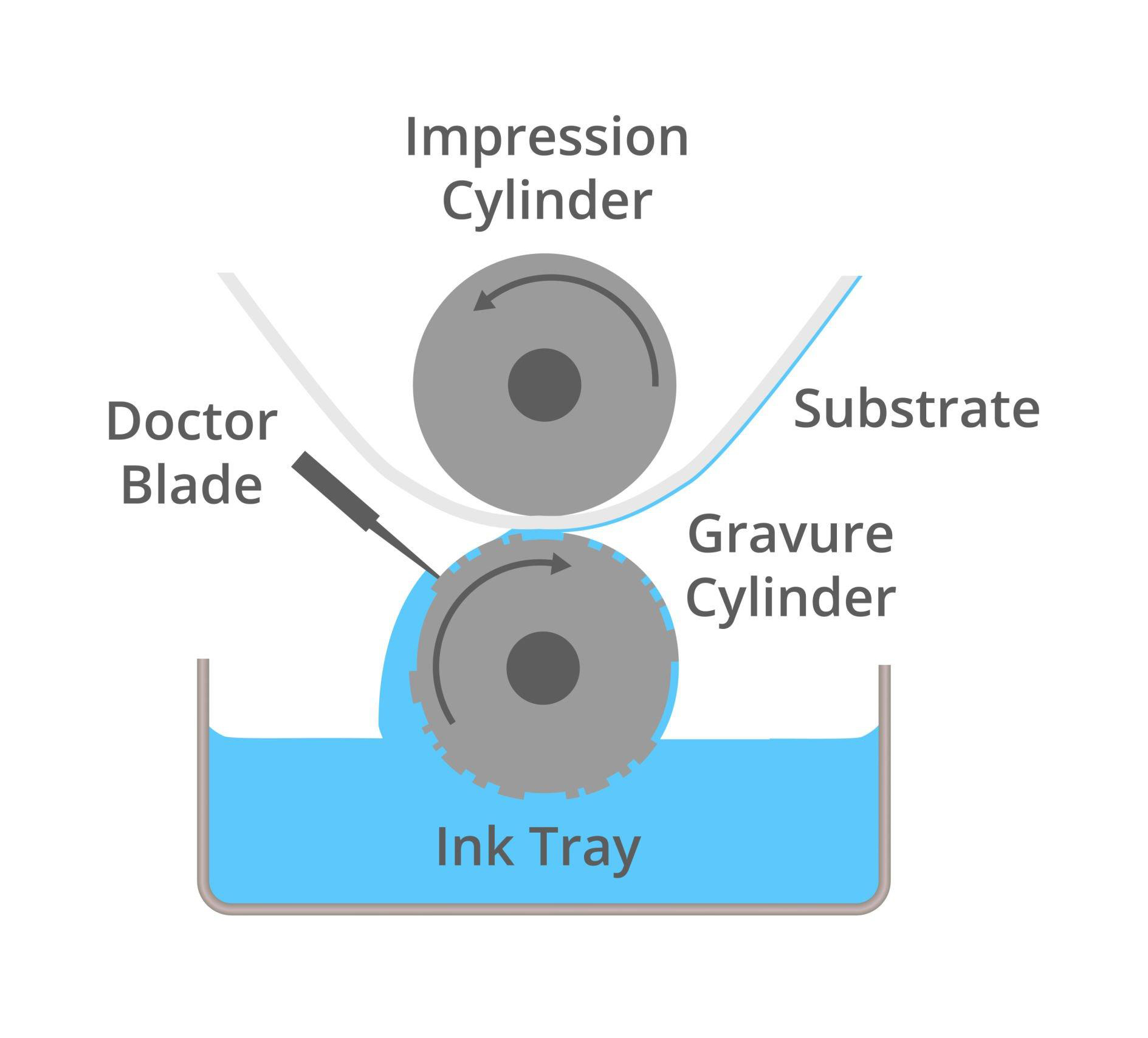

Ink Application: The cylinder is coated with printing ink and excess ink is removed from the cylinder. As the ink settles in the cavities, it is removed from the surface. The surface of the cylinder carries only the ink remaining in the cavities.

Printing Process: The printing cylinder is placed between a printing plate and the substrate (packaging material). The cylinder rotates while printing on the printing plate and then on the substrate. High spots on the printing plate transfer ink to the substrate, while low spots do not transfer ink. In this way, the design is transferred to the substrate.

This method offers a flexible approach to achieve the desired results by enabling the use of material-specific inks. Depending on the characteristics of the packaging material, special coatings and lacquers can also be used.

Rotogravure printing has many advantages. First, it ensures high print quality. Precise control of the cavities ensures that fine details, tonal gradations and shadows can be accurately transferred. This makes packaging look attractive and impressive. In addition, it is possible to achieve high-resolution and clear images.

Rotogravure printing also ensures durability. The ink settles into the grooves on the cylinder and is transferred to the substrate, ensuring the longevity of the print. The design on the packaging is less likely to fade or erode over time.

Furthermore, rotogravure printing offers limited color options. Each cylinder can only be used for one color. Therefore, designs that require multi-color or complex color transitions may require additional cylinders and printing processes.

As a result, rotogravure printing is a method often used in the packaging industry to achieve high quality and impressive prints. It provides a detailed transfer of designs and can enhance the visual appeal of packaging while strengthening the brand image. However, the specifics and demands of the projects should be taken into account, taking into account the cost and preparation time of the process.