Prepress

Graphic Design and Reproduction

During flexible packaging production, design and reproduction play a crucial role. Design determines the aesthetic appearance of the packaging and includes details such as dimensions, shape, colors, typography, and graphics. Reproduction involves preparing the design for printing. At this stage, colors are adjusted, resolution and dimensions are determined.

During reproduction, color matching tests are conducted, and the suitability of the design for printing in real life is ensured. Graphic design and reproduction contribute to the value of a high-quality packaging and attract consumer interest.

A GMG proof is a reference sample used to control print quality. This sample is created during the prepress preparation process and serves as a preview to ensure correct color usage.

A reliable GMG proof is an important method for controlling print quality and contributes to customer satisfaction. Having a high-quality GMG proof is crucial to ensure accurate color representation and achieve high-quality prints.

Cylinder Processing

Cylinder engraving is accomplished by engraving a specific pattern or print on the surface of a specially designed cylinder. This cylinder may have embossed or hollow patterns, usually created by engraving or engraving methods.

The cylinder machining process may include the following steps:

Pattern Design: The first step is to design the pattern to be applied to the packaging material. This design can be created using computer-aided design (CAD) programs or hand drawings.

Cylinder Production: The designed pattern is etched or engraved on the surface of a copper cylinder. This cylinder is usually made of steel or brass. The engraving process can be performed by laser technology, chemical processes or by hand.

Printing or Coating: The cylinder is placed in the printing or coating machine. As the material is applied to the surface of the cylinder, the pattern is transferred from the cylinder to the material. The printing or coating process can vary depending on the type of material and the desired result.

In addition to improving the aesthetic appearance of packaging, this method can enhance factors such as brand promotion, product safety and quality. In addition, cylinder processing can also improve the durability and protective properties of packaging.

Cylinder processing is an important technique used in the packaging industry and is widely used to enhance the visual appeal and expressiveness of packaging.

Ink formulation

In flexible packaging production, the ink used in the printing process undergoes a special preparation process known as “ink formulation”.

The ink formulation process is important to enhance print quality and improve production efficiency. Firstly, a customized formulation is prepared based on the requirements of the printing machine. Factors such as ink color, thickness, drying speed, adhesion properties, and durability are taken into consideration in this formulation.

Next, the necessary raw materials for preparing the formulation are combined in specific proportions. These raw materials include components such as pigments, binders, solvents, and additives.

Finally, the prepared ink undergoes a specialized mixing process. This process ensures the homogeneous mixing of ink components. After the mixing process, the ink is ready to be used in the printing machine.

The ink formulation process holds great significance in flexible packaging production. A well-executed ink formulation process enhances print quality, improves production efficiency and contributes to customer satisfaction.

Printing

Rotogravure Printing

Rotogravure printing is an intaglio printing technique used in the packaging industry. This method is preferred for achieving high quality and detailed prints and is particularly ideal for creating impressive graphics, images and text on packaging materials.

Rotogravure printing works through grooves on a cylinder. The grooves are used for storing and transferring ink. These cavities contain a combination of dots with different depths and widths. Depending on the design, the density and arrangement of these dots can vary. Deep dots store more ink, while shallow dots store less ink. Thus, different tones, shades and details can be created.

The rotogravure printing process consists of several stages:

Design Preparation: The first step is to prepare the design to be used in the print. A high-resolution image is usually created using digital design software. This design is made suitable for printing and color separations are made.

Cylinder Engraving: The design is transferred onto a copper coating on a printing cylinder using an engraving machine. Then, using methods such as acid or laser, gouges are created. The gouges contain a combination of dots with different depths and widths. Deeper dots store more ink and create darker tones, while shallower dots store less ink and create lighter tones.

Ink Application: The cylinder is coated with printing ink and excess ink is removed from the cylinder. As the ink settles in the cavities, it is removed from the surface. The surface of the cylinder carries only the ink remaining in the cavities.

Printing Process: The printing cylinder is placed between a printing plate and the substrate (packaging material). The cylinder rotates while printing on the printing plate and then on the substrate. High spots on the printing plate transfer ink to the substrate, while low spots do not transfer ink. In this way, the design is transferred to the substrate.

This method offers a flexible approach to achieve the desired results by enabling the use of material-specific inks. Depending on the characteristics of the packaging material, special coatings and lacquers can also be used.

Rotogravure printing has many advantages. First, it ensures high print quality. Precise control of the cavities ensures that fine details, tonal gradations and shadows can be accurately transferred. This makes packaging look attractive and impressive. Furthermore, it is possible to achieve high-resolution and clear images.

Rotogravure printing also ensures durability. The ink settles into the grooves on the cylinder and is transferred to the substrate, ensuring the longevity of the print. The design on the packaging is less likely to fade or erode over time.

Furthermore, rotogravure printing offers limited color options. Each cylinder can only be used for one color. Therefore, designs that require multi-color or complex color transitions may require additional cylinders and printing processes.

As a result, rotogravure printing is a method often used in the packaging industry to achieve high quality and impressive prints. It provides a detailed transfer of designs and can enhance the visual appeal of packaging while strengthening the brand image. However, the specifics and demands of the projects should be taken into account, taking into account the cost and preparation time of the process.

Technical

Solvent-based Lamination

Solvent-based lamination is the process of combining two or more different films to create a packaging material in flexible packaging. This process is accomplished using a solvent-based adhesive.

Solvent-based lamination is commonly used in packaging products that require high barrier properties. For example, it is used to preserve the freshness of food or to protect chemicals from external factors.

The solvent-based lamination process begins with the assembly of the prepared films from the previous step. The films are bonded together using a solvent-based adhesive. This bonding process is carried out using specialized equipment called a laminating machine.

During the lamination process, solvent-based adhesives are applied to the films using a specific roller. Subsequently, the films are passed through special cylinders to bond them together and keep them in place. After the process, the solvent is removed from between the films by ventilation, completing the lamination process.

Solventless Lamination

Solventless lamination is an alternative lamination method used in flexible packaging, particularly preferred in the food and pharmaceutical industries. In this method, solvents are not used to bond different materials together. Instead, alternative bonding methods such as thermal bonding or adhesive tapes are employed.

In solventless lamination, a specialized machine is used to combine different layers. This machine consists of a pressure roller, a laminating unit and a cooling cylinder for the bonding process. The materials are passed through the pressure roller to laminate the lower layer and then they are bonded onto the upper layer using the laminating unit. Finally, the material is cooled on the cooling cylinder resulting in a tightly bonded, rigid and robust laminate.

Solventless lamination offers several advantages, including improved safety by eliminating the use of solvents, reduced environmental impact and enhanced productivity due to shorter drying/curing times. It provides a reliable and efficient packaging solution that meets the stringent requirements of the food and pharmaceutical industries.

Special Varnish Application

Special varnish application in flexible packaging is typically used to create a matte, glossy, textured or metallic appearance on the surface of the packaging. Special varnishes can also enhance the durability of the packaging and improve its product protection capabilities.

Special varnish application is also referred to as a specialized printing process and is customized based on the design of the packaging. This process is often combined with lamination to achieve a higher-quality result. Special varnish application is particularly utilized in the packaging of luxury products within the packaging industry.

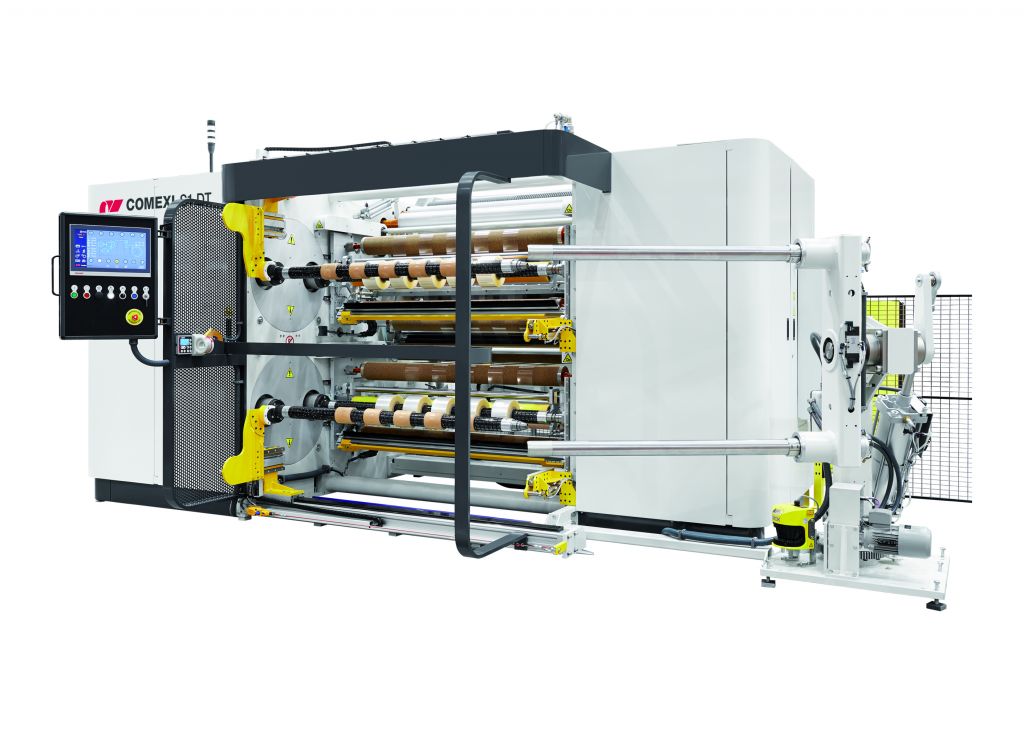

Slitting

Slitting in flexible packaging refers to the process of cutting large rolls of packaging materials into desired dimensions or widths. This process is carried out to prepare the packaging materials in sizes that align with the customer’s needs and requirements.

Slitting is typically performed automatically using precise cutting equipment. The packaging material is unwound from a roll and directed into the slitting machine. The cutting machine ensures that the material is cut into the desired dimensions and once the cutting process is complete, the pieces are gathered, packaged or directly sent to the customer. Slitting is an important step in flexible packaging production as it ensures that the packaging is cut to the correct sizes, meeting customer needs, and facilitating the secure packaging of the product.

ColdSeal Coating

Coating Cold seal in flexible packaging is a packaging method that utilizes a cold seal adhesive film. In this method, the bonding process is achieved by applying a cold seal adhesive film to the inner surface of the packaging material. The cold seal film is coated with a silicone layer to protect its adhesive surface. This type of adhesive requires less time and energy compared to hot adhesives. Cold seal films are produced in different thicknesses and sizes depending on the characteristics of the products to be packaged.

The cold seal packaging method is widely used in the food and pharmaceutical industries. By using a cold seal film layer instead of a hot adhesive layer between packaging materials, it prevents external factors such as temperature and humidity from causing damage to the product. Additionally, the cold seal method provides additional protection to the packaged products and is preferred as a cost-effective option.

Perforation

Perforation in flexible packaging refers to the process of creating holes in the packaging material in desired shapes and sizes. This process is performed for various purposes such as ventilation of the package, easy opening, removal of products, or maintaining pressure balance during the opening of the packaging.

Perforation is typically carried out on high-speed machines, similar to most other steps in flexible packaging production. Specialized perforation dies are used to create the desired holes on the materials.

Various technologies are employed for perforation, including mechanical perforation, laser perforation, and ultrasonic perforation. Mechanical perforation is typically done using high-speed cutting blades, while laser perforation utilizes laser beams to create the holes. Ultrasonic perforation, on the other hand, involves the use of high-frequency ultrasonic waves.

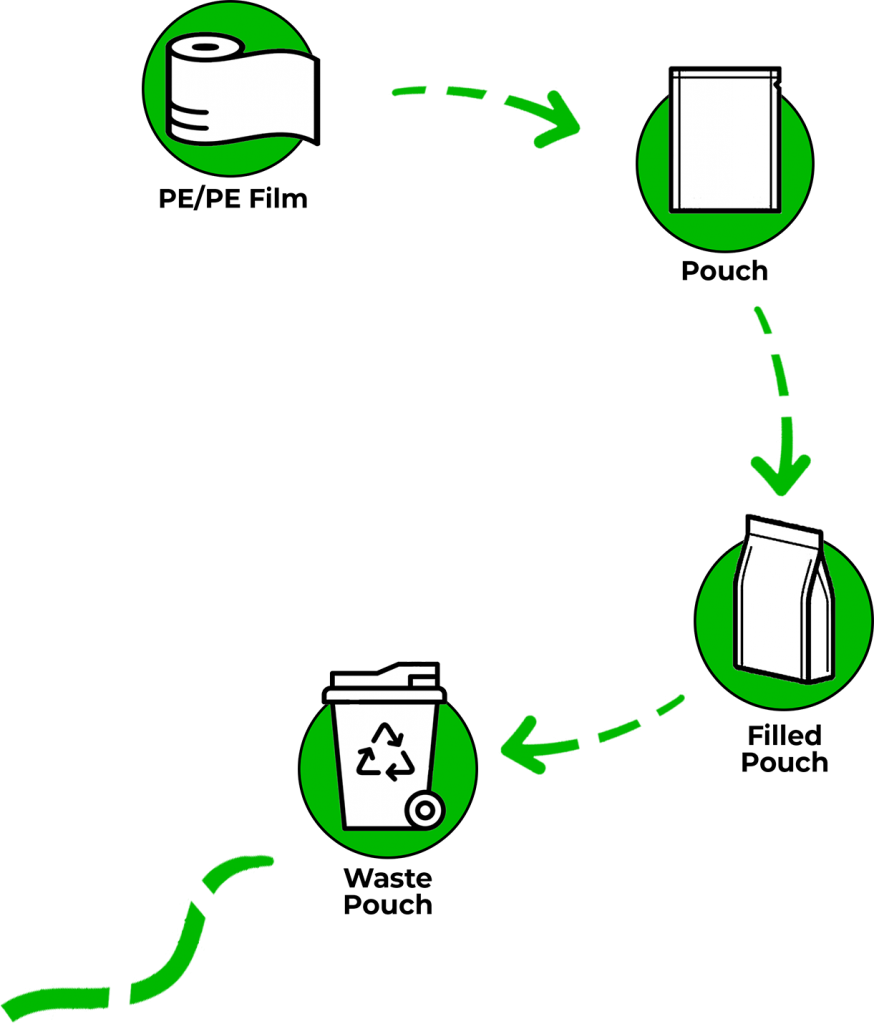

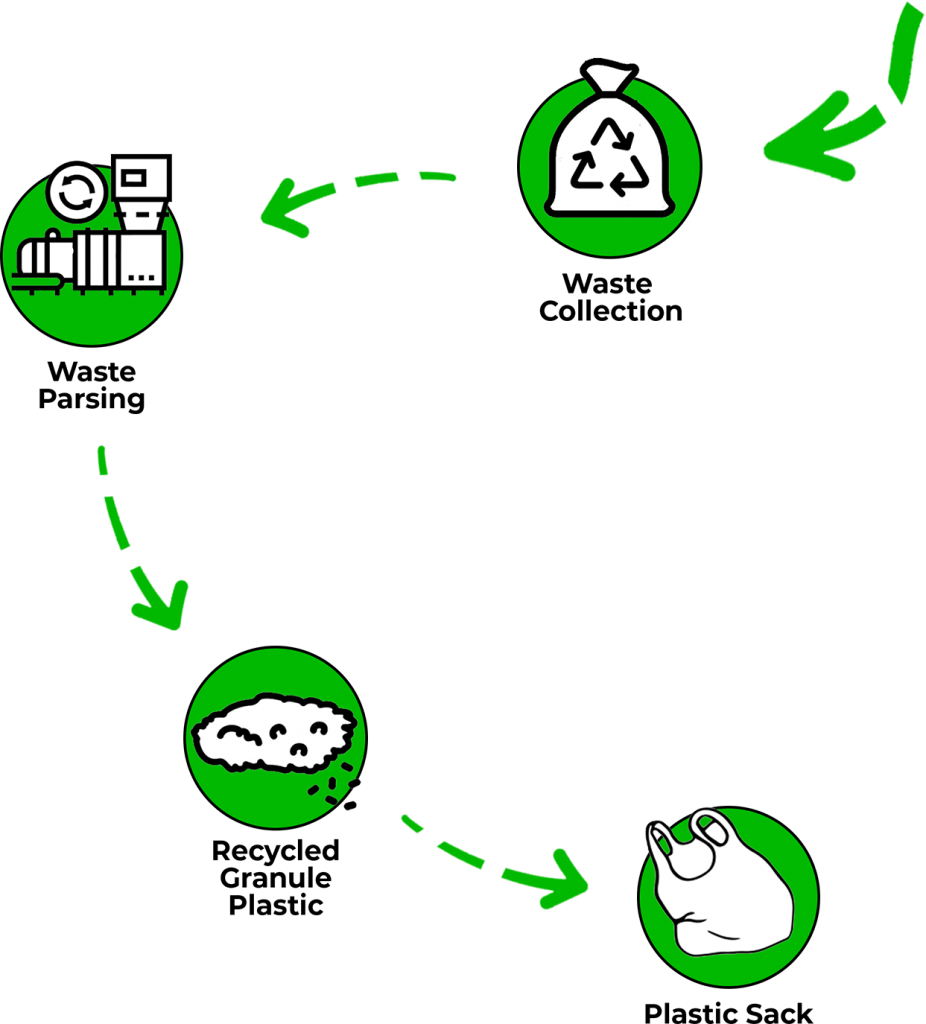

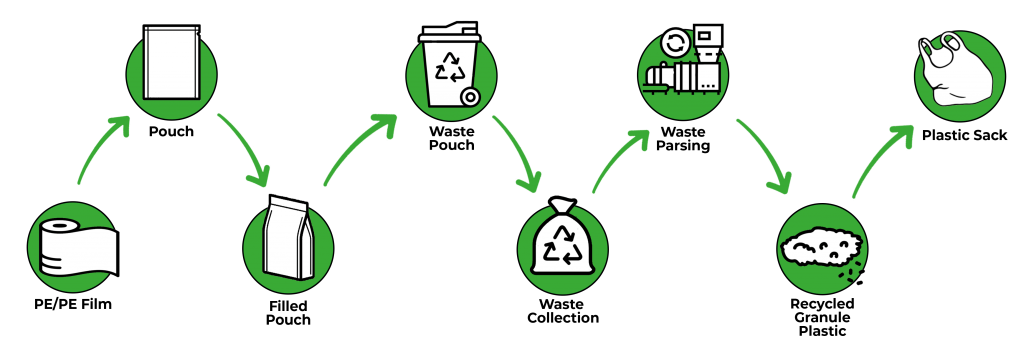

Recycling

What is Recyclable Packaging?

Recyclable packaging refers to the process of separating and collecting waste materials based on their types and converting them into raw materials through various physical and chemical processes.

The recyclability of packaging depends on the collection and recycling streams available in each country. The strategy announced by the European Commission in January 2018, aiming for a 55% and 65% increase in plastic production by 2025 and 2030 respectively, further highlights the importance of this issue.

Extending the lifespan of materials that take a long time to decompose in nature by recycling them helps reduce the accumulation of waste in the environment while also reducing the usage of such materials. Scientific reports emphasize the need for several steps to be taken in the packaging industry.

Leading and innovative brands in the flexible packaging sector, such as Krcpack Ambalaj, are making significant investments in recyclable packaging. From the use of raw materials to the production of fully recyclable packaging, the realization of such packaging is expected in the near future. Krcpack, operating with innovation, creativity, and environmental consciousness on a national and international level, allocates significant resources to enable packaging to be reused and recycled.

Recyclable Packaging

Packaging is not only a necessity that meets the basic needs of humans but also appeals to nature and animals. Additionally, packaging is one of the most widely used products in the world, driven by the increasing population and demand. Recyclable packaging can be defined as an environmentally friendly type of packaging due to its recyclability. Minimizing the harm to the environment due to the increasing population and needs is one of our company’s main goals. In line with this goal, we ensure that our packaging is 100% recyclable by using recyclable materials in our packaging.

Advantages of Using Recyclable Packaging

Example products often used in industry: Recyclable packaging for food, pet food, personal care, household cleaning, textiles and agricultural products. By favoring environmentally friendly companies that use recyclable packaging:

– The amount of waste is reduced, thus minimizing waste areas,

– Preventing raw material depletion and thus contributing to both the company and the world economy,

– Energy savings are achieved,

– Since 100% recyclable raw materials are used, waste of natural resources is reduced,

– Especially in food products, the product is protected from external factors with its extra barrier material structure.

retort

What is Retort Packaging?

Retort packaging refers to flexible laminated food packaging bags that can withstand thermal processing. Their shelf life is as long as that of metal cans. Retort packaging is considered the most significant advancement in food packaging since the introduction of metal cans. These packages are the most suitable alternative to metal cans and glass jars.

Compared to traditional metal cans, retort packaging is significantly lightweight, occupying less space and offering logistical convenience. Tin cans maintain the same volume even when empty, whereas retort packaging takes up very little space when empty.

Material selection is of critical importance in the manufacturing of heat-resistant bags. The packaging should protect against light-induced degradation, moisture fluctuations, contact with microorganisms, oxygen ingress and other interactions. The material should be structurally robust and able to withstand heating temperatures, in addition to withstanding rough handling during transportation.

Advantages of Retort Packaging

Food companies aim to transfer the food produced to the consumer with maximum confidence thanks to healthy and durable packaging. In this direction, they want to prevent the product from being damaged by temperature and pressure factors.Retort packaging is considered as an alternative to traditional and industrial canning methods.

With retort packaging:

– Since it takes up less storage space than canned products, it provides financial gains in logistics, storage and production stages.

– Provides ease of opening and transportation.

– Can be produced with three-layer or four-layer material structure.

Retort can be applied to stand-up pouch, three-side welded and shaped bag formats.

– Thanks to its material structure, it protects the product it comes into contact with against temperature, humidity and pressure effects and extends the shelf life of the product.

– The aroma and taste of the food is not impaired.

– Long shelf life.

– Retort packs are frequently used in food industries such as meat, fish, chicken, cheese, ready-made sauces, cooked ready meals, soups, appetizers, pet food, etc.