0%

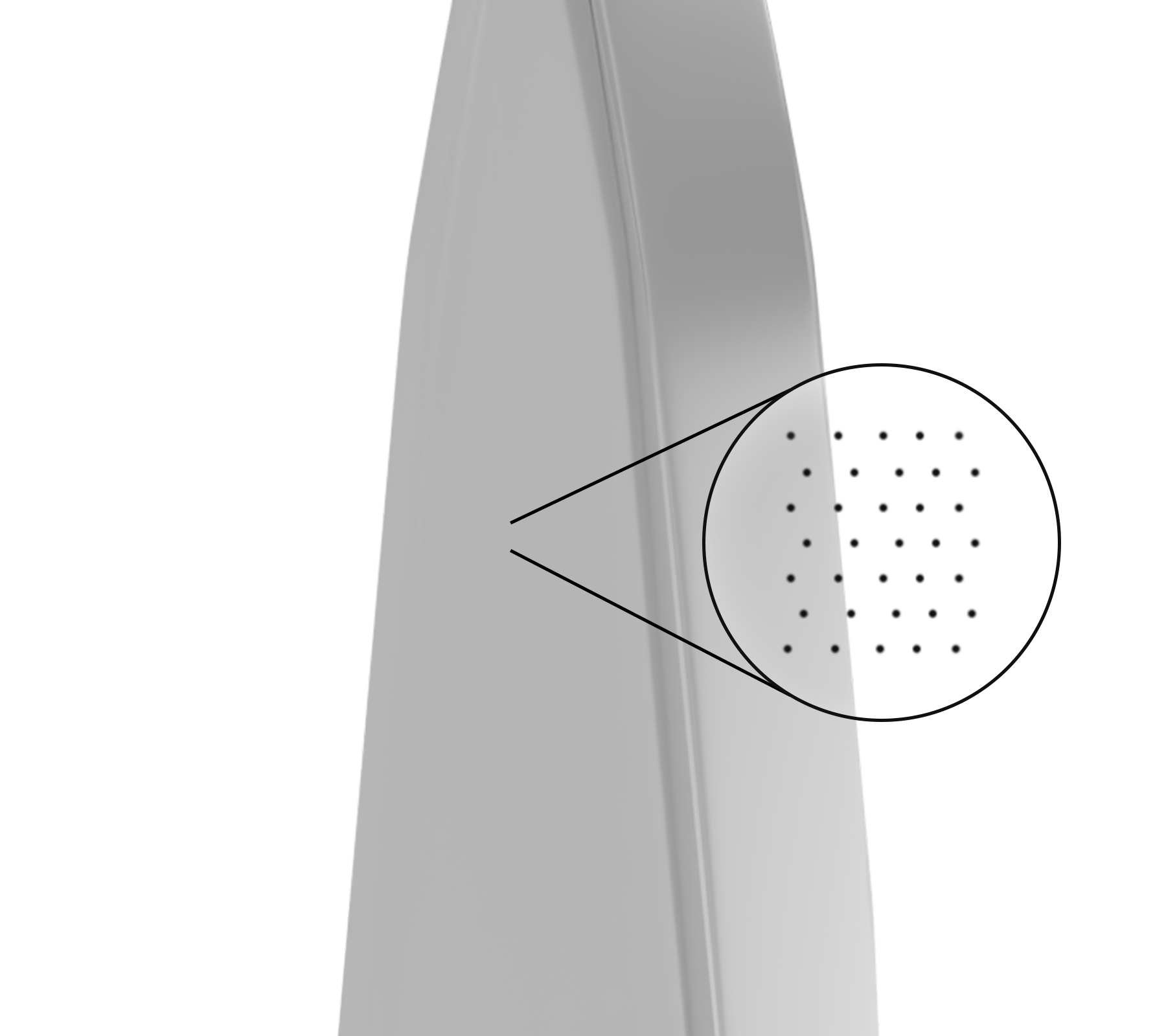

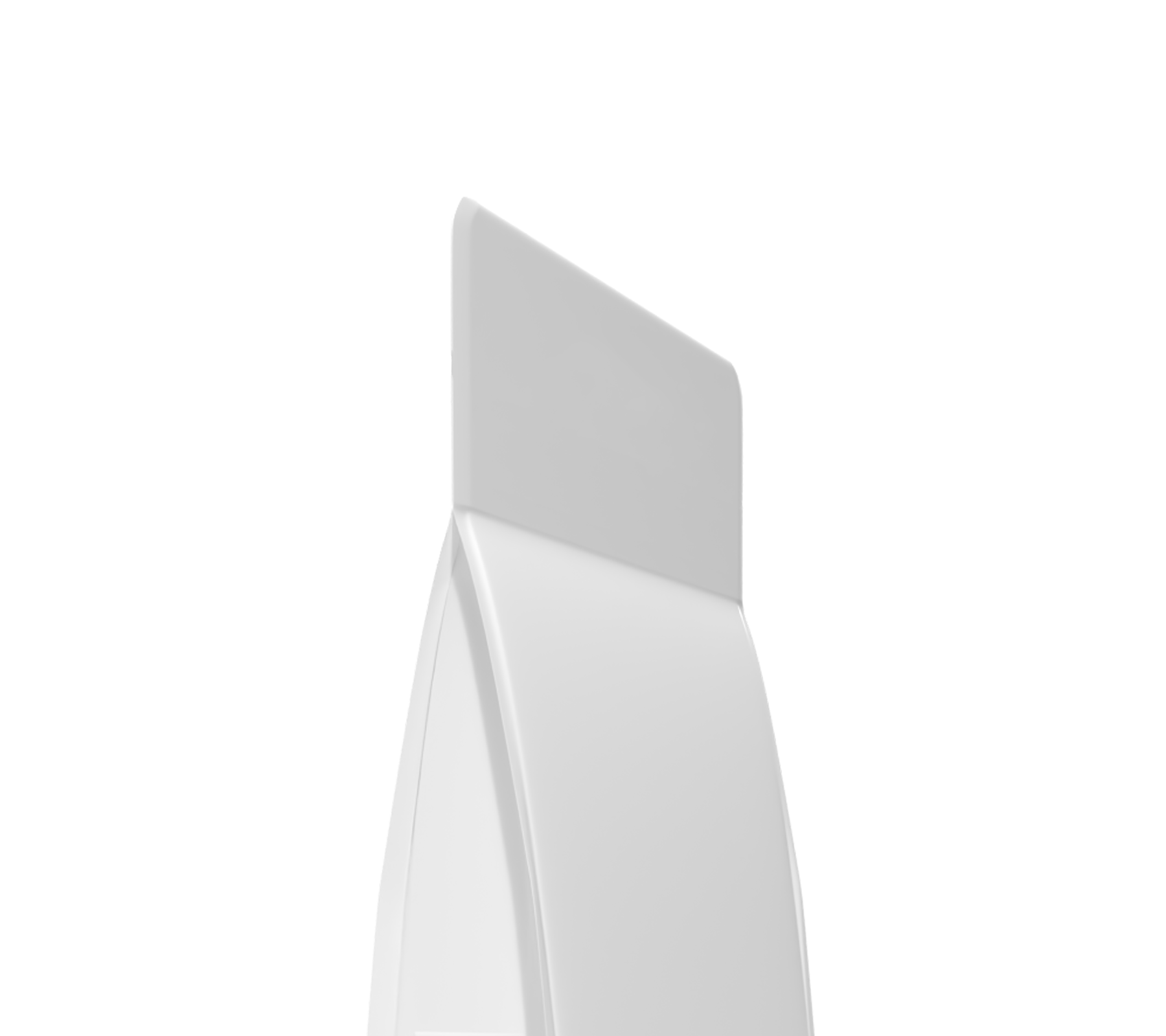

Back Seal Threehole

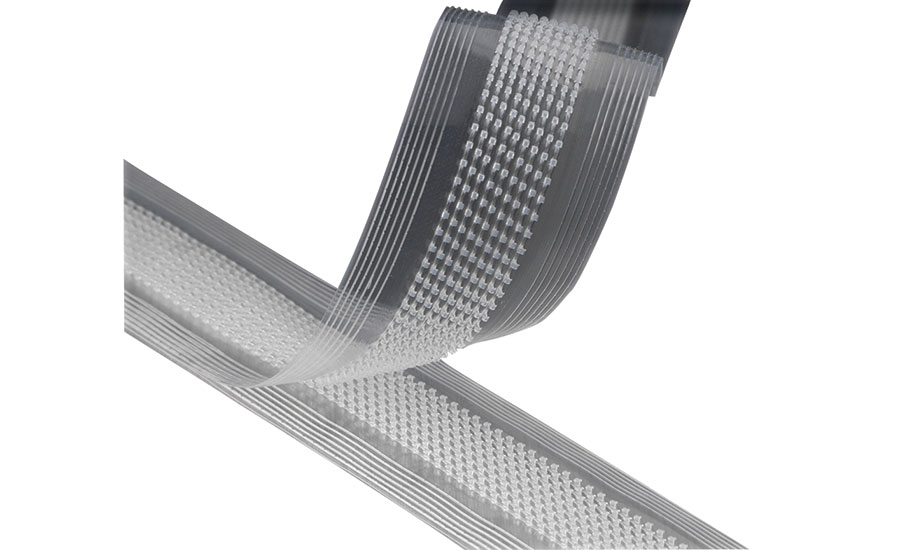

Back weld flexible packaging is a packaging solution for the protection and packaging of products. This type of packaging is created by welding or gluing together the back of the product to be packaged. Thanks to three-hole technology, you can ensure ease of transportation.

What is Back Seal?

Back-seal flexible packaging is a type of packaging used for the transportation and storage of products. These packages are typically made from a polymer such as polyethylene and are sealed in an airtight cap-like manner by gently compressing the back of the products. This helps protect the products from the effects of air and maintains their freshness for a longer period.

Back-seal flexible packaging also reduces the likelihood of product damage during transportation and enables products to have an appealing display on shelves. Additionally, these types of packaging are environmentally friendly as they are recyclable and do not generate waste after use.